When we use our fingers to lightly touch the screen of our mobile phones to unlock them, or check store information on the touch screen in the mall, every contact between our fingertips and the screen is interpreting a technological revolution that has lasted for more than half a century. As a key interface for human-computer interaction, touch screen displays have evolved from conceptual prototypes in the laboratory to a bridge connecting the physical world and the digital world.

The prototype of the touch screen can be traced back to 1965, when British engineer E.A. Johnson published a paper in Nature magazine, describing a device that detects finger position through capacitive sensing, which is regarded as the theoretical starting point of capacitive touch screens. His experimental device consists of a transparent conductive layer and a controller. Although it can only recognize single-point touch, it laid the foundation for the "finger-screen-feedback" interaction logic.

Dr. Samuel Hurst of Kent State University in the United States invented the prototype of the resistive touch screen "AccuTouch", which located the touch point by making two layers of resistive film conductive through pressure. This technology was applied to the information inquiry terminal of the Toronto World Expo in 1982, becoming the first commercial attempt at touch screen display. The "Chronicle of Touch Screen Technology" records that the resistive screen at that time needed to be operated with fingernails or stylus, and the sensitivity of finger touch was low, but it had shown the potential to replace keyboards and mice.

In the 1980s, touch screen displays were mainly limited to the military and scientific research fields. The U.S. Air Force deployed early touch screens in the cockpit of the F-16 fighter jet to simplify the pilot's operation process; NASA's space shuttle also used touch screens as control panels to meet the special operation requirements in the space environment. Although these applications were not popular, they verified the feasibility of touch screens in extreme environments.

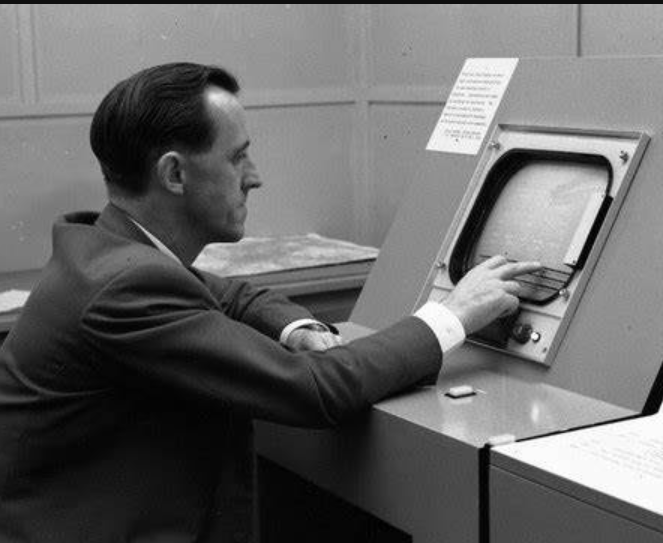

At the same time, the academic community has never stopped exploring touch screen technology. In 1985, IBM launched the first commercial computer equipped with a touch screen, the IBM 3270, which used capacitive technology, but its high cost (about $10,000) and limited functions limited its popularity. At this stage, touch screen displays were like "aristocrats in the laboratory". The technical principles were gradually becoming clear, but they were still far from the mass consumer market.

In the 1990s, resistive touch screens saw their first large-scale application. Due to their simple structure and low cost, resistive touch screens quickly became popular in POS machines, ATM machines, industrial control panels, and other scenarios. In 1993, Apple launched the Newton PDA, integrating a resistive touch screen into a consumer electronic device for the first time. Although it was controversial due to handwriting recognition accuracy issues, it opened up the exploration of touch screens on mobile devices.

The History of Consumer Electronics Technology mentions that the golden age of resistive touch screens was from 1995 to 2005, during which time they occupied more than 70% of the global touch screen market. Its technological iterations mainly focus on improving touch accuracy and durability: from four-wire resistance to five-wire resistance, touch positioning accuracy has increased from ±3mm to ±0.5mm; the number of wear resistance of the surface PET film has increased from 500,000 times to 5 million times, meeting the basic needs of industrial and commercial scenarios.

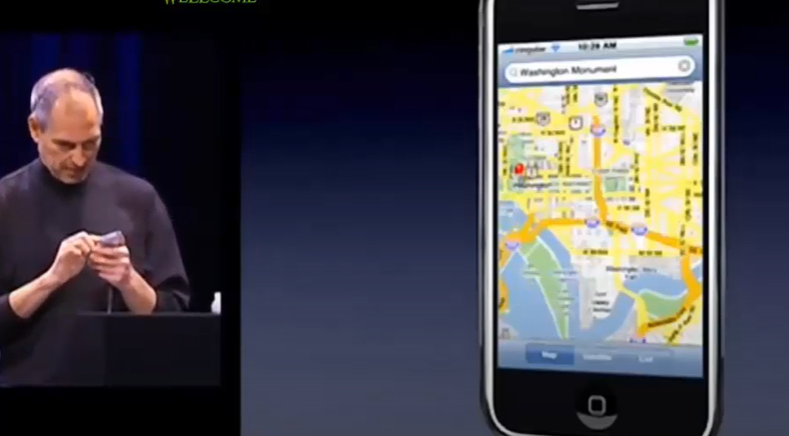

2007 was a turning point in the development of touch screen displays. The launch of Apple's iPhone brought capacitive touch screens into the mainstream consumer market for the first time. At the launch event, Steve Jobs demonstrated the magic of multi-touch by pinching and zooming a picture with his fingers. This touch screen, which uses projected capacitive technology and supports 10-point touch, combined with the gesture logic of the iOS system, completely subverted the traditional mobile phone interaction method.

The breakthrough of capacitive technology is that it solves the problem of multi-touch. Traditional surface capacitive screens can only recognize single-point touch, while projected capacitive screens (PCAP) form a capacitive matrix through row and column electrode arrays, which can accurately locate multiple touch points. "The Revolution in Smartphone Interaction Design" points out that the success of the iPhone lies not only in hardware innovation, but also in the establishment of a humanized interaction logic of "touch-feedback", which transforms the touch screen from a tool to an organ that extends human perception.

While resistive and capacitive technologies dominate the market, other touchscreen technologies are also developing in specific areas:

· Infrared touch screen : The infrared transmitting and receiving tubes at the edge of the screen form a grid, and the touch point is located when an object blocks the infrared beam. It is mainly used in large-size electronic whiteboards and public inquiry terminals.

· Surface acoustic wave touch screen : Ultrasonic waves are transmitted on the glass surface, and touch will reflect the acoustic wave signal. It was once used in bank self-service terminals, but it has been gradually eliminated due to its poor anti-interference ability;

· Electromagnetic induction touch screen : Positioning through the electromagnetic signal generated by the stylus, it is still used in drawing boards and electronic signing equipment, such as Wacom's digital tablet.

The working principle of resistive touch screen can be simplified into the three steps of "pressure-conductivity-positioning":

1. Structural composition : It consists of two layers of transparent films coated with ITO (indium tin oxide), separated by micron-sized insulating particles in the middle, and covered with hardened PET film on the surface;

2. Working process : When a finger presses the screen, the two layers of resistance film are connected at the contact point, and the controller determines the touch position by detecting the resistance change of the X and Y axes;

3. Technical features : Supports touch with any object (including gloves and stylus), but only single-point touch, low light transmittance (60-70%), and dark picture.

3M's five-wire resistive screen technology represents the highest level in this field. By leading the electrodes of the lower resistive layer to the four corners, it improves touch accuracy and durability. It is still irreplaceable in scenarios such as industrial control and medical equipment.

The core of capacitive touch screen is the accurate perception of electric field changes:

1. Capacitive sensing : The ITO conductive layer on the screen surface forms a uniform electrostatic field. The contact of a finger changes the contact capacitance, and the controller locates by detecting the capacitance change.

2. Projected capacitive technology : Etching row and column electrodes on a glass substrate to form a capacitor matrix. Each intersection is a sensing unit that can detect multiple contacts at the same time.

3. Technology upgrade : The self-capacitance type (detecting the change of capacitance of a single electrode) has evolved to the mutual capacitance type (detecting the change of coupling capacitance between electrodes), and the touch accuracy has been improved from ±1mm to ±0.1mm.

Apple's TrueTone technology and Samsung's Super AMOLED touch integration solution represent the pinnacle of capacitive touch screen technology. They not only achieve high-precision touch, but also deeply integrate the touch sensor with the display panel, improving the screen's transmittance and durability.

Early touch screens were like an additional layer "pasted" on the display, but modern technology has achieved deep integration of the two:

· G/G structure : glass-glass touch layer, high strength but heavy, early iPhones used this structure;

· G/F structure : glass-film touch layer, thin and light but less durable, widely used in mobile phones and tablets;

· On-Cell/In-Cell technology : Embed the touch sensor inside the display panel, such as the In-Cell technology after iPhone 5, making the screen thinner and more transparent;

· OLED and touch integration : In a flexible OLED screen, the touch layer can be directly made on top of the organic light-emitting layer, realizing true "screen and touch integration".

In the consumer space, touchscreen displays have become standard:

· Smartphones : According to Statista data, 92% of smartphones worldwide will use capacitive touch screens in 2023, with multi-touch and gesture operations becoming the basic interaction methods;

· Tablet computers : iPad and other devices combine touch screens with styluses, turning tablets from entertainment tools into productivity devices. A survey by a design school showed that the use of styluses increased students' homework efficiency by 40%.

· Smart home : The touch panels of smart refrigerators and smart speakers enable intuitive operation of complex functions through the touch screen. A user survey of a smart home brand shows that the learning cost of the touch interface is 60% lower than that of traditional buttons.

In commercial scenarios, touch screen displays play a key role:

· Retail industry : Self-service cash registers in supermarkets, virtual fitting mirrors in clothing stores, and touch screens make the shopping process more efficient. Walmart’s case shows that self-service cash registers shorten checkout time by 50% and increase store traffic by 20%;

· Healthcare : The hospital's self-service registration machines and touch terminals in wards support operation with gloves and are easy to disinfect. Statistics from a tertiary hospital show that touch terminals have reduced the average waiting time for patients from 45 minutes to 22 minutes.

· Education : Interactive electronic whiteboards, smart desks, and touch screens allow for more frequent classroom interactions. After a middle school’s experimental class used touch-screen teaching equipment, student participation in class increased by 55%.

In professional scenarios, touch screen displays demonstrate special value:

· Industrial control : For factory human-machine interfaces (HMIs) and CNC machine tool operation panels, resistive touch screens are the first choice due to their resistance to oil and scratches. A case study of an automobile production line showed that the error rate of touch operation was 70% lower than that of traditional buttons;

· Design and creation : Graphic workstations with touch screens and digital screens support precise drawing with pressure-sensitive pens. Wacom Cintiq series touch screens account for more than 80% of the animation production market and are widely used by studios such as Pixar.

· Aerospace : Modern aircraft cockpit displays mostly use capacitive touch screens, which, combined with anti-false touch algorithms, can still be accurately operated in high-G force environments. The Airbus A350 cockpit touch system reduces the pilot's operating steps by 30%.

With the advancement of technology, the application scenarios of touch screen displays continue to expand:

· Wearable devices : The application of flexible touch screens in smart watches and AR glasses has achieved miniaturized interaction. The bending radius of the flexible touch screen of a certain brand of smart watches can reach 5mm, which is suitable for wrist wear;

· Car central control : Tesla Model S's 17-inch touch screen redefines in-car interaction, enabling more than 90% of functional control through touch, driving the entire automotive industry's transformation to large-screen touch;

· Virtual reality : The touch controllers of VR headsets and the touch panels of AR glasses expand touch interaction from two-dimensional screens to three-dimensional space. The positioning accuracy of the touch controllers of Oculus Quest 2 reaches ±1mm, enabling precise operation in the virtual world.

· Durability challenge : The bending life of flexible touch screens is usually around 100,000 times, which is still far from the million times required for daily use;

· Power consumption : Large touch displays consume 15-20% more power than non-touch models, which affects battery life in mobile devices.

· Environmental adaptability : The touch accuracy of capacitive screens decreases at extreme temperatures (below -20°C or above 60°C), and the display effect of resistive screens is poor under strong light.

· Ultrasonic touch : It locates touch by emitting ultrasonic waves and detecting reflections. It can penetrate materials such as glass and plastic and is suitable for hidden touch in smart home devices.

· Optical touch : Use the camera to identify finger movements and achieve air touch, which can reduce the risk of contact transmission in public health scenarios;

· Haptic feedback technology : simulates the touch of physical buttons through vibration and pressure feedback, such as Apple's 3D Touch technology, to enhance the sensory experience of touch;

· AI-driven touch optimization : By using machine learning algorithms to predict user operation intentions and reduce false touches, a mobile phone manufacturer's AI touch optimization has reduced the false touch rate by 45%.

· Multimodal interaction fusion : The touch screen is combined with voice, gesture, eye tracking and other interaction methods to form a more natural human-computer dialogue. Microsoft's Hololens 2 has achieved seamless switching between touch and gesture;

· Smart surface technology : Integrate touch functions into various surfaces, such as desktops, car doors, walls, etc., so that any flat surface can become an interactive interface;

· Biometric integration : embed fingerprint, palm print, and even blood vessel recognition functions in the touch screen to improve security and simplify operations. A bank's ATM has piloted the touch screen fingerprint payment function;

· Environmental protection and sustainable design : Develop recyclable ITO alternative materials (such as graphene) to reduce the consumption of rare metals; design modular touch screens to facilitate maintenance and upgrades, thereby extending the life cycle of the equipment.

From EA Johnson's capacitive sensing experiment in 1965 to the popularization of billions of touch devices around the world in 2023, the development history of touch screen displays can be called a "history of technological revolution at your fingertips." It has not only changed the way we interact with machines, but also reshaped the forms of information acquisition, content creation, commercial services and many other fields.

In the foreseeable future, touch screen displays will no longer be limited to the physical form of "screens", but will be integrated into every aspect of our lives, becoming a seamless interface between the digital and physical worlds. When our fingertips touch the screen, we are not just touching a piece of glass or film, but also the eternal pursuit of human beings for a more natural and intuitive way of interaction. From a concept in the laboratory to a necessity in daily life, the story of touch screen displays is the best interpretation of how technology changes our lives.

Name: lily

Mobile:185 7332 9919

Tel:185 7332 9919

Whatsapp:8618573329919

Email:sales@huayuan-lcd.com

Add:Factory No.9, Zhongnan High-tech Intelligent Manufacturing Industrial Park, Tianyuan District, Zhuzhou,Hunan, China, 412000