In the fields of LED lighting, display screens, automotive lighting, and other applications, proper connection methods are crucial to ensuring the normal operation and service life of LEDs. The three most commonly used LED connection methods are series, parallel, and hybrid (series-parallel) wiring. Each method has unique circuit characteristics, application scenarios, and advantages/disadvantages. This article delves into the technical principles of these connection methods and provides a scientific selection guide.

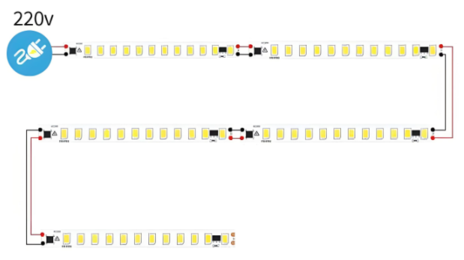

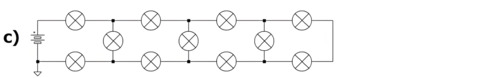

A series connection involves linking multiple LEDs end-to-end to form a single current path. In a series circuit, the current flowing through each LED is identical, as governed by Kirchhoff's Current Law (referenced from Circuit Analysis by Charles K. Alexander and Matthew N.O. Sadiku). This characteristic ensures uniform luminous intensity, making it ideal for scenarios requiring consistent brightness, such as linear lighting fixtures. For example, in high-end hotel corridor lighting, series-connected LED strips provide soft and even illumination, creating a comfortable ambiance.

Advantages of series connection include simple circuit design—only one constant-current driver is needed to power multiple LEDs—and reduced energy loss due to lower system current (aligned with Joule's Law principles, though formulas are omitted for readability). Take LED streetlights as an example: series-connected LEDs significantly reduce energy consumption and extend fixture lifespan.

However, series connections have notable drawbacks. If one LED in the circuit fails open, the entire circuit is interrupted, causing all LEDs to extinguish, which severely impacts reliability.

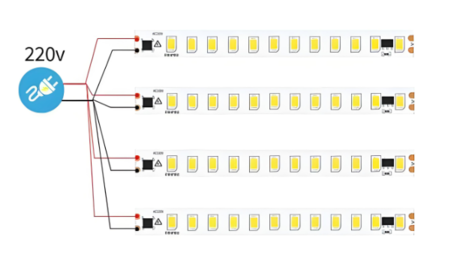

A parallel connection links the anodes and cathodes of multiple LEDs directly to the power supply, creating independent current branches. In a parallel circuit, the voltage across each LED is the same, as defined by Kirchhoff's Voltage Law (referenced from Fundamentals of Electric Circuits by David Irwin). This method suits applications requiring multiple LEDs to work simultaneously with individual control, such as dimmable fixtures in smart lighting systems. In smart home setups, users can adjust the brightness and color of each parallel-connected LED via a mobile app, enabling personalized lighting.

Key benefits of parallel connection include high reliability—failure of one LED does not affect others—and lower voltage requirements for drivers. For instance, in decorative lighting using numerous low-power parallel LEDs, partial failures have minimal impact on overall illumination.

However, parallel connections have limitations. When many LEDs are paralleled, the driver must supply a large total current, placing high demands on its output capacity. Additionally, slight variations in forward voltage (even among same-batch LEDs due to manufacturing tolerances) can cause uneven current distribution, affecting light output consistency.

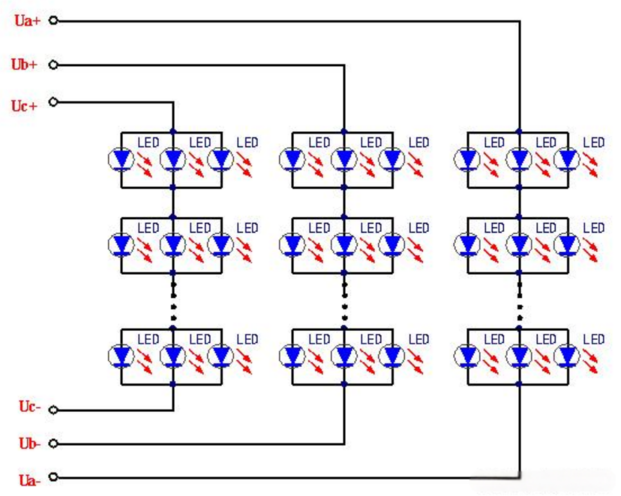

Hybrid connection merges the advantages of series and parallel wiring by first grouping LEDs into series strings, then connecting these strings in parallel to the power supply. This topology balances voltage and current requirements, reduces the impact of single-point failures through modular control, and minimizes the number of current-limiting resistors.

Hybrid wiring excels in high-power, multi-LED applications that require flexibility in matching power supply parameters. For example, in LED streetlights or large display screens, a well-designed hybrid structure (e.g., 3 series strings × 4 parallel strings) ensures both brightness uniformity and fault tolerance. However, hybrid circuits demand precise calculations for LED grouping and power supply specifications, requiring advanced technical expertise. Fault diagnosis is also more complex compared to pure series or parallel setups.

When selecting an LED connection method, consider the following factors:

Constant-current sources: Prioritize series or hybrid connections.

Constant-voltage sources: Opt for parallel or hybrid connections.

High-stability scenarios (e.g., outdoor lighting): Prefer parallel or hybrid wiring.

Low-cost, low-risk applications: Series connection is suitable.

High-power applications: Use parallel or hybrid wiring to scale current capacity.

Uniform brightness requirements: Choose series or carefully optimized hybrid configurations.

Series: Lowest cost but poorest fault tolerance.

Parallel: Requires more current-limiting resistors, increasing complexity.

Hybrid: Balances performance but demands sophisticated design.

For practical applications, refer to international standards such as IEC 62031:2008 LED modules for general lighting – Safety requirements and combine with environmental factors (e.g., temperature, humidity) and product lifespan expectations.

Series, parallel, and hybrid LED connection methods each offer distinct advantages and trade-offs, with no universal "best" solution. By understanding their circuit principles and aligning them with specific application needs, engineers can maximize LED efficiency, energy savings, and longevity. Whether for lighting, displays, or automotive systems, a scientifically chosen connection method ensures reliable performance and technical optimization.

Name: lily

Mobile:185 7332 9919

Tel:185 7332 9919

Whatsapp:8618573329919

Email:sales@huayuan-lcd.com

Add:Factory No.9, Zhongnan High-tech Intelligent Manufacturing Industrial Park, Tianyuan District, Zhuzhou,Hunan, China, 412000